To ride the motorcycle you will have to shift gears successfully, and to do that the clutch plates have to disengage and engage while you pull in the clutch lever. The motorcycle clutch not disengaging will damage the parts of the clutch assembly and will result in clunky/harsh gearshifts, and not fixing this problem on time will lead to the costly replacement of a whole clutch unit.

In this article, we will go through 9 major reasons why your motorcycle clutch is not disengaging and how to fix each of these issues properly to get proper functioning and longevity out of your motorcycle’s clutch whether they are cable clutch or hydraulic clutch.

Also, we go through some symptoms of the clutch not fully disengaging and easy prevention tips to maintain the good condition of your motorcycle’s clutch.

So you would ask yourself why does my motorcycle clutch not disengage? Here are the most common reasons for motorcycle clutch not disengaging and how to fix each one of them.

Table of Contents

1. Wrong Motorcycle Clutch Free play

The right amount of motorcycle clutch lever free play is very important for the clutch to engage and disengage completely to avoid any kind of unwanted friction.

No clutch lever free play or a wrong amount of free play will cause the clutch to slip or drag. In this case, where the motorcycle clutch is not disengaging will create a clutch drag issue.

How To Fix

A recommended motorcycle clutch lever free play on average is between 10-20 millimeters, where the clutch plates can fully disengage and not get stuck creating a dragging clutch problem.

You can measure the clutch lever free play by placing a measuring tape from the end of the clutch lever to the motorcycle grip (handlebar’s end).

The clutch lever should have 10-20 mm free play from its starting point where the lever is fully extended before the clutch starts disengaging or starts getting into the friction zone.

An alternate way of measuring an accurate amount of free play for your after-market clutch levers because often they are small and does not have the size and length of OEM clutch lever is to adjust the free play of a 2-4 mm perch gap at the start of the clutch lever where the pivot point bolt of the clutch lever is located.

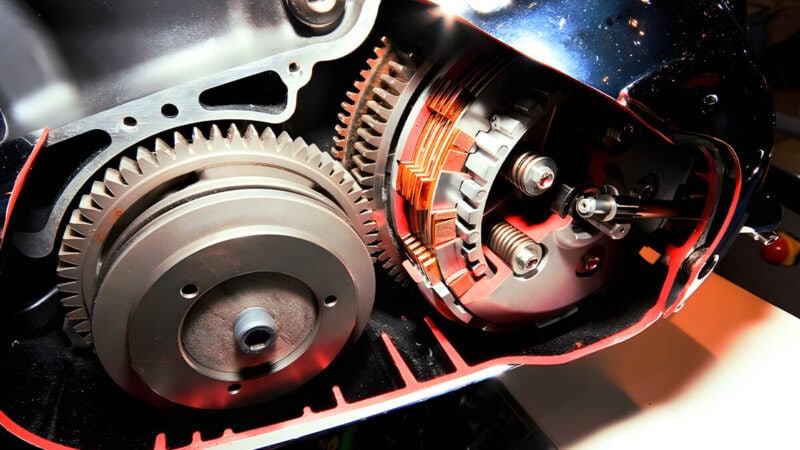

2. Grooves Or Indents On Clutch Basket Fingers

A damaged/worn clutch basket will have deep/rough grooves or indents on the clutch basket fingers.

These rough or deep grooves on the clutch basket fingers will cause the friction plates of the clutch pack to get stuck in them, which will result in the motorcycle clutch not disengaging.

How To Fix

There are two ways to smooth out the grooves or intent on the clutch basket fingers.

First, you could get the grooves on the clutch basket fingers professionally filed (metal file) by a certified mechanic. As too much smoothing out of the basket fingers will increase the finger gap and the clutch pack won’t stay in its place/come loose.

The second option to fix your damaged/grooved clutch basket fingers is to replace the whole clutch basket with a new one. Replacing the damaged clutch basket is a much safer option.

3. Chipping Or Damaged Teeth Of Clutch’s Inner Hub

The inner hub of the clutch holds and rotates the steel plates of the clutch pack in its place.

Chipping of the inner hub’s teeth/splines will either cause the steel plates to get stuck in between the ridges of the chipped part of the inner hub or become way too loose.

Continuing to shift/change gears under this condition will have clunky gear shifts and will significantly damage the clutch pack as a whole.

How To Fix

The teeth or splines on the inner hub of the clutch hold the steel plates of the clutch pack in place. So damaged teeth of the inner hub will leave no option than completely replacing it.

Replacing the damaged inner hub will let the clutch pack rotate properly and will fix the problem of the clutch not disengaging.

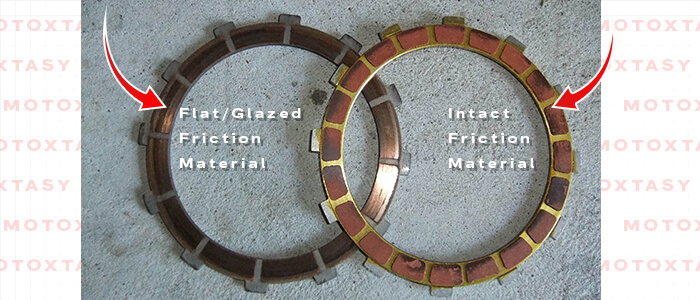

4. Worn Clutch Friction Plates

A perfect way to spot worn clutch friction plates is to look at the integrity of friction material and the outer circumference teeth of the friction plates.

A worn clutch friction plate will have a very thin or no friction material left on its surface.

This friction material creates a grip between friction plates and steel plates of the clutch pack and also avoids both of these plates directly coming in contact with each other to avoid direct friction and damage to these plates.

Also, look for any chipping or damage to the teeth of friction plates that go in between the clutch basket fingers.

How To Fix

If the layer of friction material on the friction plates is significantly thin/less or completely faded or the teeth of the plates have any kind of bent or chipping, then you should replace the friction plates of the clutch pack.

5. Worn/Damaged Clutch Steel Plates

Worn clutch steel plates will generally have signs of bluing and burn marks on their surface. On the other hand, a severe sign of significant damage is the wrapping or bending of clutch steel plates.

You can easily check the whole clutch pack for any kind of damage by removing the clutch cover, clutch spring bolts, and pressure plate placed on top of the clutch pack.

How To Fix

You can remove the bluing or burn marks on the surface of clutch steel plates by soaking them in acetone liquid for 3-5 minutes and buffing them with a twisted wire-wheeled buffer.

If the clutch steel plates have any signs of wrapping or bending then it needs to be replaced immediately.

6. Wrong Adjustment Of Clutch Cable Being Too Loose

The motorcycle clutch not disengaging can easily be caused by a loose clutch cable and the wrong length of the clutch cable will also cause an incorrect adjustment to the whole clutch setup.

Wrong adjustment of the clutch cable at the adjuster screw/barrel adjuster will cause further damage to the crucial clutch assembly components like the clutch pack, clutch housing/basket, and inner hub.

Too much slack in the clutch cable or the clutch cable being too loose will not disengage the clutch even when you pull in the clutch lever completely.

How To Fix

First, install the correct length of clutch cable for your motorcycle by referring to your motorcycle owners/service manual and adjust the right amount of clutch lever free play of 10-20mm from the end of the clutch lever or perch gap of 2-4mm from the start of the lever.

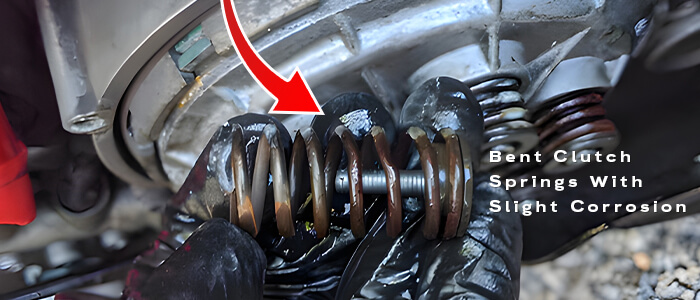

7. Bent or Corroded Clutch Springs

The clutch spring and bolts go on top of the clutch pack with the pressure plate on.

The clutch springs modulate the clutch lever feel and the movement of the clutch pack. As heavy clutch springs make the clutch lever heavy/harder to pull, and soft clutch spring makes the clutch lever feel lighter.

If your motorcycle clutch lever is harder to pull or super tight then read this article to quickly fix that problem.

Bent or corroded clutch springs will cause the clutch to not disengage as it will stop the friction plate and steel plate from separating when you pull in the lever.

How To Fix

Replacing the corroded or bent clutch spring is a safer and ideal option for maintaining the integrity and longevity of the motorcycle clutch.

8. Hydraulic Clutch Master or Slave Cylinder Seal Leak

Motorcycles with hydraulic clutch systems require less maintenance compared to the cable clutch setup, but maintaining and changing the clutch fluid (brake fluid) from time to time is necessary for a well-functioning clutch.

Not bleeding the hydraulic clutch lines or seal leak of the master or slave cylinder of the clutch system will your motorcycle clutch to not disengage.

Your motorcycle will lurch forward even when you pull in your clutch lever.

How To Fix

You can replace the worn/damaged seals to stop the seal leak of the hydraulic clutch master or slave cylinder.

An alternative option you can choose is to buy a rebuilt/repair kit for your motorcycle’s master or slave cylinder. And most of the time the repair/rebuilt kit will include a replacement hard anodized aluminum piston, replacement cover screws, boot, and spring.

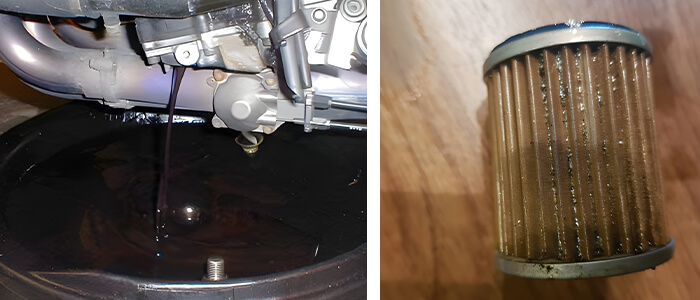

9. Contaminated Engine Oil & Dirty Oil Filter

Engine oil is crucial for lubrication of the whole clutch assembly and proper functioning.

Using old engine oil and not changing the oil filter which is often dirty will keep the contaminants/dirt and small chaffed metal shavings/particles of the engine due to wear and tear circulating inside the engine and clutch assembly.

Contaminated Engine oil will turn sticky and cause the clutch pack to stick together causing the motorcycle clutch to not disengage.

Storing the motorcycle for a long time can also cause the clutch plates to stick together. But it all depends on the engine oil quality, the time when it was last changed, and the condition of the motorcycle clutch.

How To Fix

Change your motorcycle’s engine oil regularly along with its oil filter. But before replacing the old engine oil, warm up the engine to get the oil hot which will help the oil and come out easily with no leftovers behind.

Symptoms Of Clutch Not Fully Disengaging

Here are some of the most obvious easy-to-spot symptoms of clutch not fully disengaging you could look out for which will save you a lot of time.

- Clunky Gearshifts.

- Grinding Noise During Downsift & Upshift.

- Stalling At Low Speed.

- Motorcycle Shutting Off During Idling.

- Motorcycle Lurching Forward

Clunky gearshifts or grinding noise during upshifting or downshifting happens when the clutch is not disengaging fully.

Stalling at low speed or the motorcycle lurching forward is an obvious sign of the clutch not fully disengaging because you will pull in the clutch lever to keep the motorcycle running and disengage the power to the rear wheel.

So these are the top most obvious symptoms/signs every rider should look out for if they are in doubt about their motorcycle’s clutch functioning.

How To Disengage Motorcycle Clutch

A quick way to disengage motorcycle clutch is to start the motorcycle in neutral gear and pull in the clutch lever multiple times while moving the motorcycle back and forth.

The heat of the running engine should free up the stuck clutch plates and trying to shift gear can also do the trick.

Keep in mind that the motorcycle will shut off a few times during the early try.

If your motorcycle clutch assembly or clutch cable is not well lubricated or damaged, lubricating it and replacing the damaged parts will bring your motorcycle’s clutch to proper working condition.

You can read the top reasons for your motorcycle clutch not disengaging and how to fix each one of them at the start of this article.

Easy Prevention Tips For Motorcycle Clutch Not Disengaging

Lubricating the clutch cable once or twice a year or maintaining the clutch/brake fluid in the master cylinder for hydraulic clutch motorcycles once a year will go a long way in preventing the motorcycle clutch from not disengaging.

Regularly changing your engine oil and oil filter is a crucial component for the efficient lubrication of your motorcycle’s clutch

Adjusting the clutch lever free play and excessive slack or tightness of the clutch cable every year is a must. (For regular riders)

Conclusion

Keep in mind that ultimately worn/damaged clutch assembly parts and clutch cable with wrong cable adjustment will cause a clutch to not disengage.